Graviner mk6 oil mist detector user manual

Posted onOctober 12, 2023

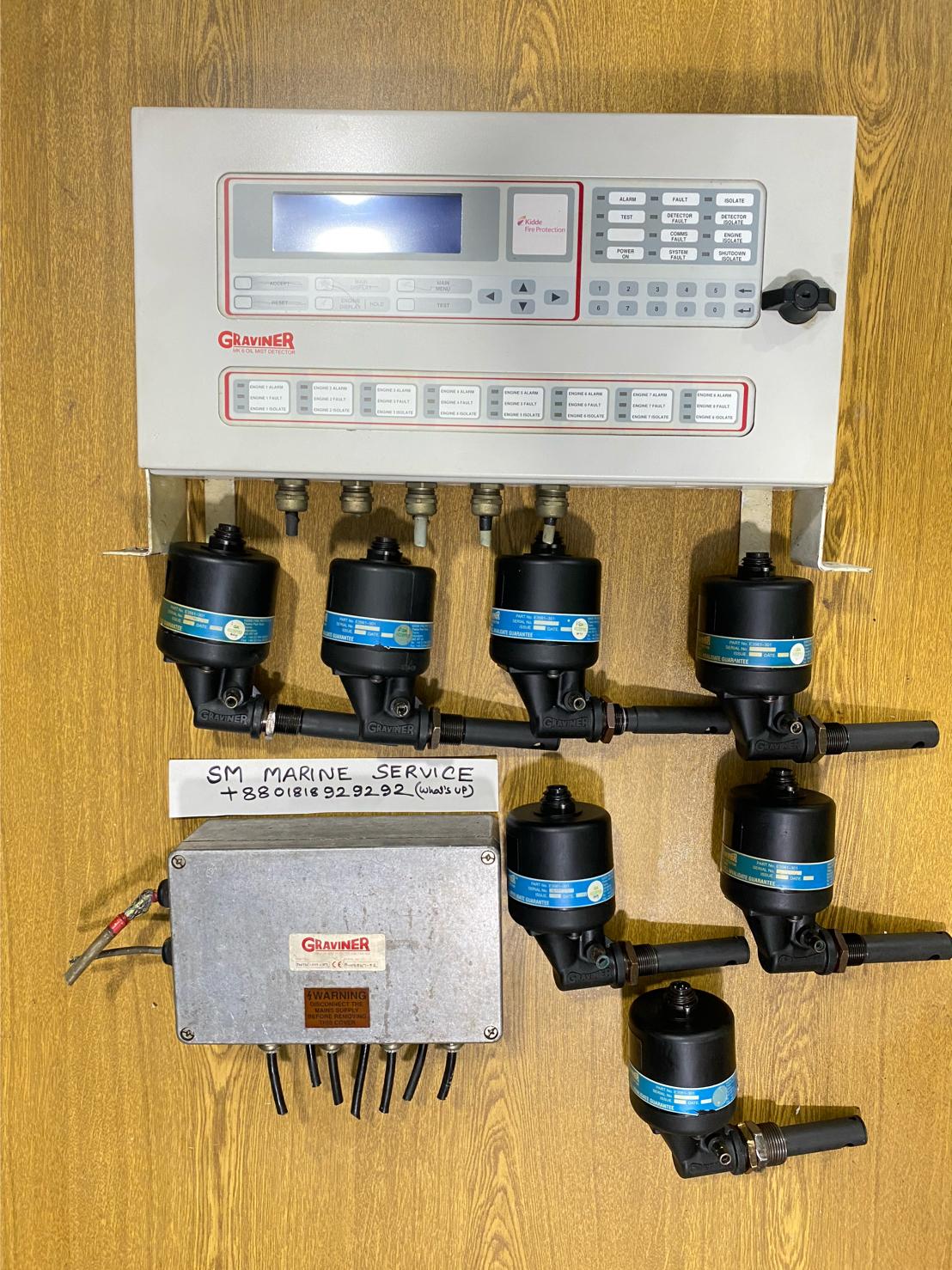

Graviner MK6 Oil Mist Detector

Scroll down to find the PDF File

Under the International Association of Class Societies (IACS)

- Engines with a bore size above 300mm

- Engine output greater than 2,200kW (2,950hp)

- Engine room routinely unmanned

Oil Mist Detectors (OMD’s) are an integral part of critical safety systems designed to detect certain conditions that could lead to crankcase explosions on large Diesel engines. They are typically installed in harsh operating conditions - particularly with respect to temperature and vibration - and are expected to provide continuous service over extended periods. They are therefore subject to considerable wear and tear.

High temperatures, in excess of 200oC that occur on bearing surfaces under initial failure conditions, can lead to a rapid generation of oil vapor When the hot vapor contacts the relatively cooler atmosphere of the crankcase it condenses into a fine mist, with typical particle sizes of around 0.5 to 5 microns in diameter. When the density of these particles reaches between 30 to 50 mg/I (Milligrams per liter), depending upon the type of oil, an explosive condition exists.

A fire or explosion needs three constituents: fuel, oxygen and an ignition source. Remove one of these and no explosion will occur. Similarly, within the crankcase, the three constituents which could cause an explosion are air, oil mist and an ignition source, the “hot spot’. Using optical measuring techniques, oil mist density can be measured at levels as low as 0.05 mg/I and give early warning of a rise in oil mist density.

Oil Mist Detection (OMD) techniques have been used to monitor diesel engine crankcases for potential explosive conditions and early detection of bearing failures. The systems available rely mainly on analysing the optical density of oil mist samples drawn from the crankcase compartments, through pipes to the Detector. While these systems proved successful in the past, engine design has improved significantly over the years and oil mist detection techniques have improved substantially to maintain adequate protection.